DoB Inspection for Gears - record trend at just 8 paisa per gear for multiple gear hobbing / grinding machines

Applications and benefits of Gear DoB Inspection

DoB / DuB inspection

Benefits

Manual v/s DoBSmart

DoB / DuB inspection

Automated DoB Inspection of Gears

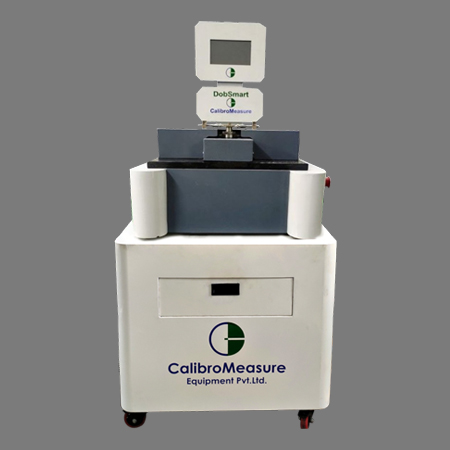

DobSmart® is the only in-process DoB inspection equipment for precision gear manufacturers, which will ensure that the setting of your hobbing/grinding machine is always 100% right, the process is always in green zone due to quick correction factor and at just 8 paisa/pc. Get warning pop up when the process is using wide tolerance ban, analyse hob life,fluctuation in DoB values beyond 20μ with real time process trend plotting and readymade correction factor.

Benefits

Industry 4.0 ready features like

Gear Tester Data saved against QR code and transferred in real time to server.

Process operation

Setting gear tester process made so easy that an unskilled operator can do it.

Zero rejection

GearMate calculates and compensates the “master runout” for ensuring zero rejection skipping to customer

PDI reports

Automatic and instant PDI reports for gear inspection process.

Ensure TCE/TTE detection

Nick detection feature detects gears making noise even when TCE/TTE are within the tolerance span..

Manual v/s DoBSmart

Manual Gear DoB Inspection method

- Manual calculation of correction factor for setting of hobbing/grinding machine

- Skilled operator required

- No assurance of inspection frequency being followed

- Inspection data not recorded for CpCpk.

- Difficulty to monitor process trend

- Human dependent decision

- Data for hob life analysis not recorded

DobSmart ® Gear DoB Inspection

- Readymade correction factor and history of correction factor available!.

- Inspection skills not required -Auto inspection

- Missed inspection pop-up!

- Missed inspection opportunities recorded!

- Auto recording of inspection data thus easy CpCpk!

- Real time process trend available on screen

Watch video

DoB Inspection - CTQ Parameters

- TTE (fi), TCE (Fi)

- Gear CD range – 45 mm to 120 mm

- Length of shaft – Up to 250 mm

- Gear OD(for shaft) – 10 mm to 85 mm

- Repeatability – +3u

- Setting time – Within I min

Shift to most advance way of gear inspection

Setting process made so easy that unskilled operator can do it

Case Study

Automation ensures zero PPM rejection in internal gear inspection

Blog

Build an impeccable process to avoid losses

Learning by sharing

Auto Gear Roll Tester to inspect 5 parameters and 9 variants

Inspection of Gear by checking 16 parameters on 4 variants in

Gear Rolling Tester – Operator conducted two tests simultaneously single-handedly. Labour-dependent

Gear inspection method for automation Your gears are examined meticulously in