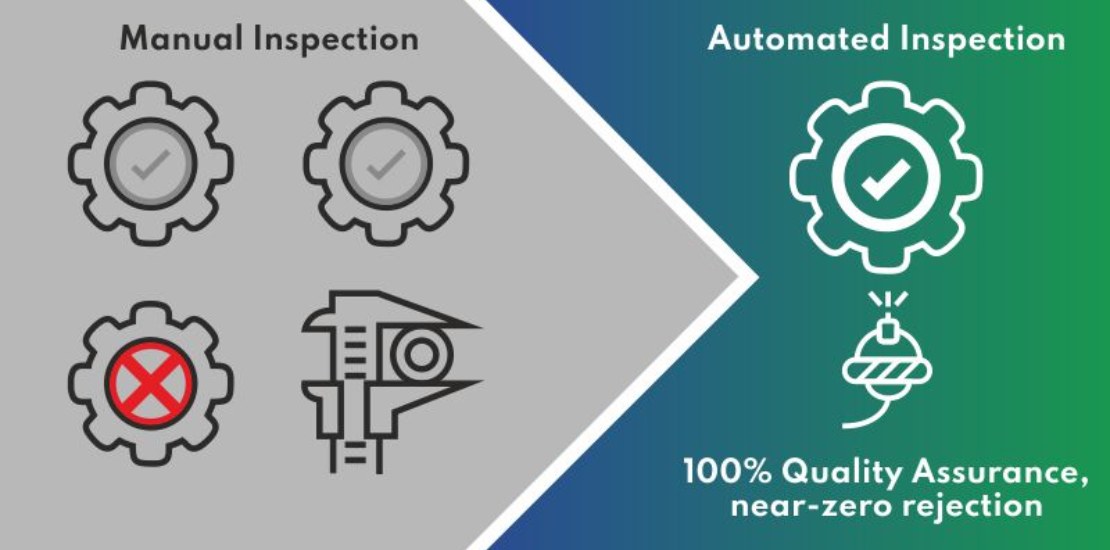

When manufacturing machines are old or start after a gap following maintenance or setting, gear quality often suffers initially. Apart from that, manual inspection is often unable to detect certain errors. If the experienced and skilled personnel leave and are replaced by inexperienced employees, the reliability of the in-process inspection process could suffer.

How do you build an inspection process that retains quality throughout?

Automating in-process gear inspection eliminates your reliance on skilled personnel and keep the process quality intact even if the machine operator or the production machine changes.

Imagine that a machine now helps ensure that the setting of your hobbing/ grinding m/c are 100% right all the time during in-process inspection. Additionally, it makes the inspection digital. You can now record as well as monitor the inspection data in real time.

DobSmart®, the in-process DoB tester does that and more at the cost of just 8 paise per piece

What’s more, your in-process inspection is now always in the green zone due to the quick correction factor for the hobbing/cutting machine.

Here’s how DobSmart® can boost your quality

- Ready-made correction factor and history of correction factor recorded.

- Missed inspection pop up

- Missed inspection opportunities recorded!

- Auto recording of inspection data, thus, easy CpCpk

- Real time process trend available on screen

- Data for hob life analysis available

And the story doesn’t end here

You can also automate gear-rolling and gear roll testing and get quantified TCE, TTE readings which are impossible to obtain with manual testing. Consider a machine that is able to roll the gear and record inspection data by itself. This again eliminates the need for skilled personnel to roll the gear.

RollSmart®, the automatic roll tester brings an added advantage

Again, at a cost of just 8 paise per piece, you could record inspection data and ensure an easy CpCpk-something which is not done in the manual inspection. RollSmart® also monitors your process and offers warning popups if something is amiss.

Advantages of RollSmart®

- Quantified TTC, TTE readings.

- Auto rolling

- Ok/ Not Ok decided by RollSmart

- Setting time- within a minute

- Missed opportunities recorded and data ready for analysis

- Auto recording of inspection data, thus easy CpCpk!

Automating the right process with the right machines is the key to resolving issues with labour, quality, and efficiency of in-process inspection. To explore how automating the inspection process can help you hit the golden mean between cost and quality, get in touch with us!

Drop a Whatsapp message to +91 9822032062 and we will send you a video of automation solutions in action!