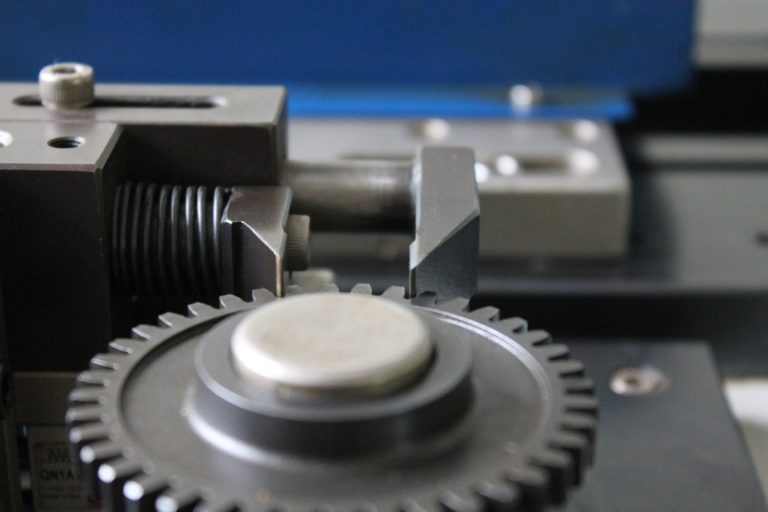

Gear Roll Tester and In-process gear inspection method

Gear production is one of the most difficult tasks to be found in modern manufacturing. A need for a shop floor inspection system, allowing for realtime inspection of gears in various stages of production without the need for skilled setup. CalibroMeasure brings you a advance gear shaft dimensional inspection, gear roll tester and gear in process gear inspection technology.

You can’t hit a perfect six with a poor quality bat.

For a good game, the skills of an athlete must match with the best quality equipment, and the CMD of this Maharashtra-based company was well aware of that. His company being focused on exports, the quest for the best had become a part of the company’s DNA. The firm made it a point to source the best quality equipment from across the globe for all aspects of gear manufacturing.

With German gear testers and French DoB fixtures, this company’s production game was geared for precision, but there was one problem.

Having quality production equipment but no inspection machinery matching the same standard was like getting a bat made of quality wood, but lacking fine attributes such as good grip and a thicker middle part suitable for playing attacking shots.

They needed the right solutions to strengthen the quality of their gear inspection process to match that of their world class production.

The seriousness of this issue was highlighted by one particular event.

The company received an order from a European client to manufacture critical machine parts in large volume. In this case, the precision and quality of the product was key, and so was the quantity. The firm now needed an gear inspection process that ensured detailed inspection at large scale.

Highest standard for quality measurement in gear inspection.

On RollSmart, the gear is rolled automatically and entire inspection data is quantified and recorded. Thus, the CpCpk analysis becomes easy and foolproof. Auto-rolling feature also leaves no option for the operator but to inspect the gear at the desired frequency.

Its automatic gear rolling, capability to test all gear and non gear parameters, and detailed digital data generation made CalibroMeasure’s final gear inspection solution GearMate the best fit the perfectionist firm’s requirements, and the deal was sealed for the machine.

But soon, there was another twist in the tale. The firm realized that automating the final gear inspection was only half the battle won. To ensure precision in its products at high volume, it would need an inspection process that was foolproof and efficient at every stage. Automating in-process inspection would nearly eliminate the chance of faulty parts reaching the final inspection. It would save time and costs spent on reworking these rejected parts.

Complete set of in-process gear solutions from CalibroMeasure.

Precise TTC and TTE measures from our in-process gear roll tester RollSmart and auto-inspection abilities of our DoB tester DoBSmart only served to add to the firms reputation for quality in all aspects-the gears and the machines. Alongside a quality production equipment, the firm now had high-precision automated inspection machinery to complete its quest for quality.

Now, it could be sure of highest precision in each piece at all stages. It was confident of hitting a six for every ball.

Reach out to us at connect@calibromeasure.com

To see the product in action, drop a Whatsapp message to +91 9822032062 and we will send you a video!