There was a time when the very thought of driver-less cars seemed a joke of the kinds you see only in James Bond movies i.e. just good to see but not likely ever to be used in real life.

And then came a new reality; that they COULD be used in every-day life effectively and efficiently with ride quality possibly much, much better than most humans could ever endeavor! Some of the earliest reasons for a driver-less car and (very, very much applicable in the Indian context) was the sheer drudgery of driving long, long distances, and the incidences of accidents with the human elements either going lax or being overwhelmed by things like too may interferences, signals and directions, etc.

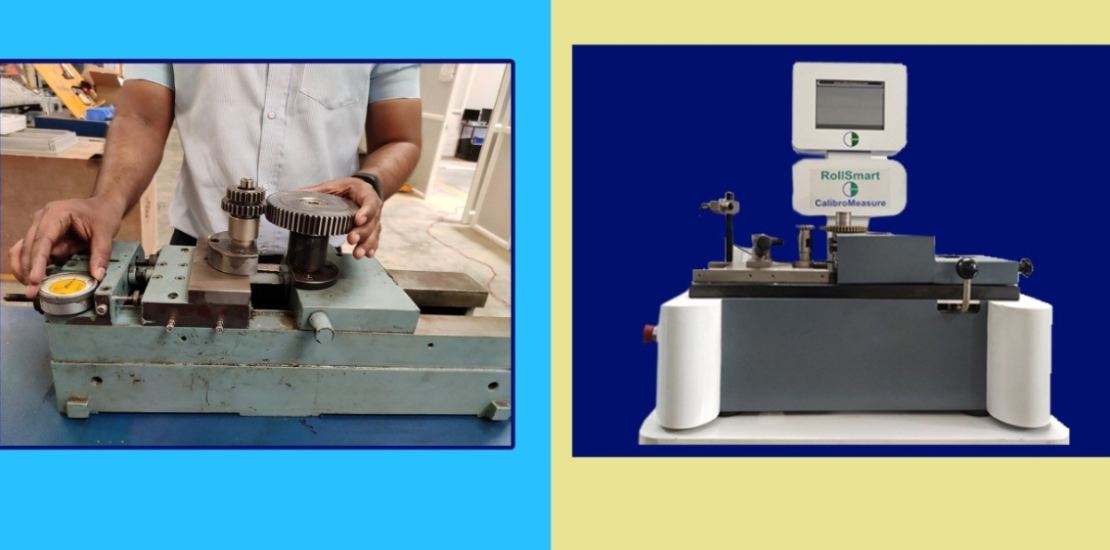

Now juxtapose the same problems with nearly the same set of elements into the world of high-precision gear manufacturing and you would see the reason a manual roll tester does not come anywhere near CalibroMeasure’s RollSmart the advance gear roll tester!

- Both these competing technologies fall within the purview of in-process gear inspection, a system inherently designed to concentrate more on the process of production than the product itself such that the final product is derived defect-free or with severely-reduced defects. And this is precisely the point where their similarity ends! In fact, other than the fact that both cater to the same idea of in-process gear inspection, there is precious little of similarity. We tell you more below.

1. Gear inspection – Machine dependent vs Human dependence

When it comes to precision at high speeds, there’s no alternative to machines. Humans just cannot cope up with the speed and accuracy of gear roll testing machine. One slip here or the oversight of just a second is all there is for a variance to creep in and go undetected. With machines, these eventualities NEVER take place.

Besides the sheer speed of activities is the fact that the gear roll tester machines do not need constant monitoring. Humans do. They can be absent, not attentive on the job and may have fifty other issues that may directly affect operations and consequent product quality. For machines, there are no such considerations. Once you switch them on, the only reason they might falter could be due to finite reasons which in most cases is within the operator’s capacity to rectify.

2. Gear Tester speed of operations and number of operations

Continuing from the above, humans just cannot match gear roll testing machines when it comes to speed of operations per minute. A manual tester takes time as the human element has to take the part from one operation to another on the same table. The gear roll tester does this in less than 30 sec. and one can thus add more test parameters for better reading and output.

3. Manual data records vs auto gear roll testing smart data records

For a human to report observations means the process has to be stopped till the details have been noted. Also, in most cases, noting means making entries on a diary or register which has then to be transferred to a machine, all of which take time. Another thing about manual reports is that they cannot be changed according to needs from one standard format. In the case of fully-mechanized operations including gear inspections, reports are a direct outcome of the onboard computer which aids in the collation of various customized reports, one among which also deals with pointing out variances!

4. Notification of rejection and spotting of sudden abnormal change in parameter value

Humans have their inherent senses which are more attuned to guide us in a natural setting. For example, the sense of understanding, visual, and record keeping & maintain. But when it comes to gear inspection machines, an operator’s natural abilities are of no use as the gear roll tester machines check all the parameters of gear and find the reason for the variances. Machines do better in these circumstances. Also, machines can record specific instances of variances and points at and from which variances started to occur.

5. Regularity of gear inspection

A manual tester needed to be told when inspections have to commence. A mechanized avatar of the same is pre-programmed to do the same at regular intervals without the need to be reminded. This is a big, big advantage that a mechanized system has over manual system given that things get very, very regular and sure.