Gear Rolling Tester Applications and benefits

Gear Roll Tester

Benefits

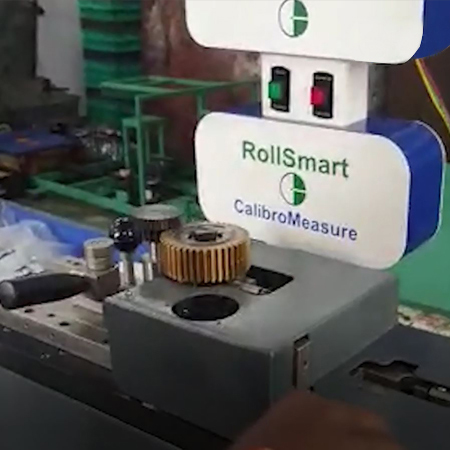

Manual v/s RollSmart

Gear Roll Tester

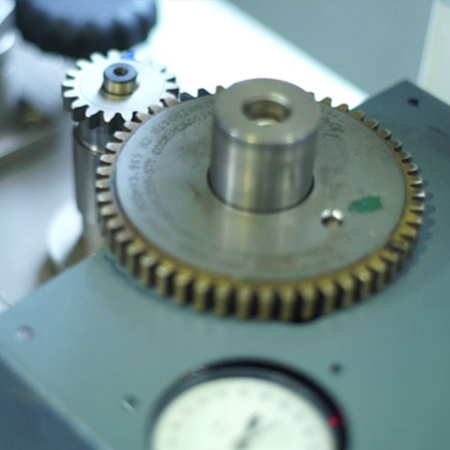

Gear rolling tester for composite error testing

RollSmart is the only In-process Roll tester that leaves no option for the operator but to inspect at desired frequency, monitor multiple hobbing/grinding machines for performance, and record the trend of TCE at just 8 paisa per gear !! Composite testing of gears entails measuring the variation in center distance while the gear is being rolled in a tight mesh with the master gear. RollSmart works as an efficient and reliable gear roll tester, also making it possible for the operator to monitor multiple gear hobbing and grinding machines at a time. Computerised steady rolling of gears by ROllSmart also contributes to preserving the master gear and extending its service life.

Benefits

Industry 4.0 ready features like

Gear Tester Data saved against QR code and transferred in real time to server.

Process operation

Setting gear tester process made so easy that an unskilled operator can do it.

Zero rejection

GearMate calculates and compensates the “master runout” for ensuring zero rejection skipping to customer

PDI reports

Automatic and instant PDI reports for gear inspection process.

Ensure TCE/TTE detection

Nick detection feature detects gears making noise even when TCE/TTE are within the tolerance span..

Manual v/s RollSmart

Manual Gear Rolling Tester

- No assurance of ‘zero’ rejection

- No traceability or accountability

- Difficulty in locating exact tooth error

- Dependence on skilled manpower

- PDI Report generation is tedious

RollSmart Gear Rolling Tester

- Zero rejections skipping PDI

- Excellent ROI

- Assured customer delight

- Service support within 24 hours

- Eliminate line stoppages due to gear rejection

Watch video

Gear Rolling Tester - CTQ Parameters

- Span measurement (attribute/ quantified type)

- Diameter Over Ball (DOB/MOT) (attribute/quantified type)

- Center distance

- PCD runout of splines/ gear

- Internal Diameter

- Outer Diameter

- Face runout & various other runouts

- Lengths

- Groove width & groove distance

- Diameter Under Ball (DUB)

- TCE/TTE of internal gears

Shift to most advance way of gear inspection

Setting process made so easy that unskilled operator can do it

Case Study

Automation ensures zero PPM rejection in internal gear inspection

Blog

Manual roll tester vs CalibroMeasure’s RollSmart

Learning by sharing

Auto Gear Roll Tester to inspect 5 parameters and 9 variants

Inspection of Gear by checking 16 parameters on 4 variants in

Gear Rolling Tester – Operator conducted two tests simultaneously single-handedly. Labour-dependent

Gear inspection method for automation Your gears are examined meticulously in