15+ Years of Expertise in Gear Quality Inspections

India’s Top Gear Exporters trust our solutions for their critical components

Innovative inspection automation for measuring what was considered unmeasurable

Gear Quality Inspection Challenges

- Complex geometry and surface finish.

- Difficult to achieve accurate, consistent measurements.

- Requires specialized tools for tooth profile and alignment checks.

- Detecting cracks or inclusions often needs destructive testing.

Delivering zero-defects, with up to 80% lesser manpower and 100% traceability

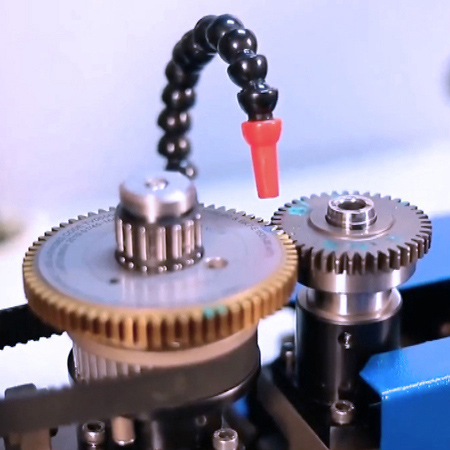

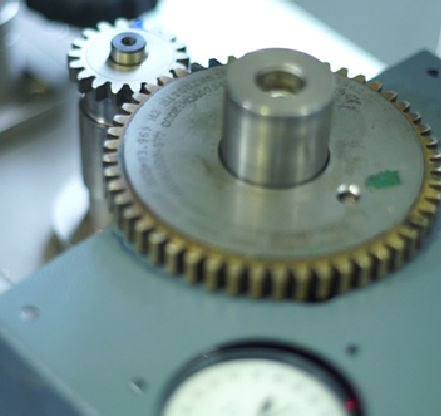

Spur/Helical Gear

Inspecting the quality of spur or helical gears poses certain challenges. Achieving accurate and consistent measurements can be difficult due to the complex geometry and surface finish of the gears.

Spur/Helical Gear

Inspecting the quality of spur or helical gears poses certain challenges. Achieving accurate and consistent measurements can be difficult due to the complex geometry and surface finish of the gears.

Spur/Helical Gear

Inspecting the quality of spur or helical gears poses certain challenges. Achieving accurate and consistent measurements can be difficult due to the complex geometry and surface finish of the gears.

Overcome every challenge in gear quality inspection

High Operator dependency?

High overheads in quality inspection?

Lack of traceability?

Only attribute based inspections?

High set-up time/cycle time?

Lack of compliance, repeatabiility, accuracy?

Real Success Stories

Solving critical gear inspection challenges

Complete range of automated gear roll testers for quality inspection

- Zero Defects. Flawless Gear Inspection. Maximum Efficiency.

- CalibroMeasure delivers total solutions in gear quality inspection!

- Backed by industry’s top experts in precision measurement.

- Experience free trials tailored to your actual components.

- Unmatched support to keep your inspection systems running at peak performance.

Identify Inspection cost savings of up to INR 5 Lakhs, instantly!

Book a call with our Experts today!

Here to answer to all your questions

Since our founding in 2007, we are leading the industry with disruptive innovations in quality inspections

- Measuring the unmeasurable

- Digitising your traditional fixtures

- Designing world-class Inspection Gadgets

- Introducing one of the most advanced 3D CMM for Shop floor inspections