The quality team at a renowned gearbox manufacturer was frustrated

and overwhelmed. Inconsistent gear quality from vendors, coupled with

error-prone manual roll testing, led to painfully high rejection rates. Day

after day, they watched financial losses helplessly. With no clear solution

in sight, the team had reluctantly accepted the issue as normal.

The quality team at a renowned gearbox manufacturer was frustrated

and overwhelmed. Inconsistent gear quality from vendors, coupled with

error-prone manual roll testing, led to painfully high rejection rates. Day

after day, they watched financial losses helplessly. With no clear solution

in sight, the team had reluctantly accepted the issue as normal.

The team struggled and felt the pressure

Team struggled with unpredictable quality

Consistent assembly became quite challenging

Team felt the pressure of relying on manual tester

Manual roll testers and mechanical dials led to human error, missed defects and incomplete inspections.

High rejection; 15% rework was unacceptable

Significant losses in time, money, and productivity.

100% Inspections with 100% Reliability

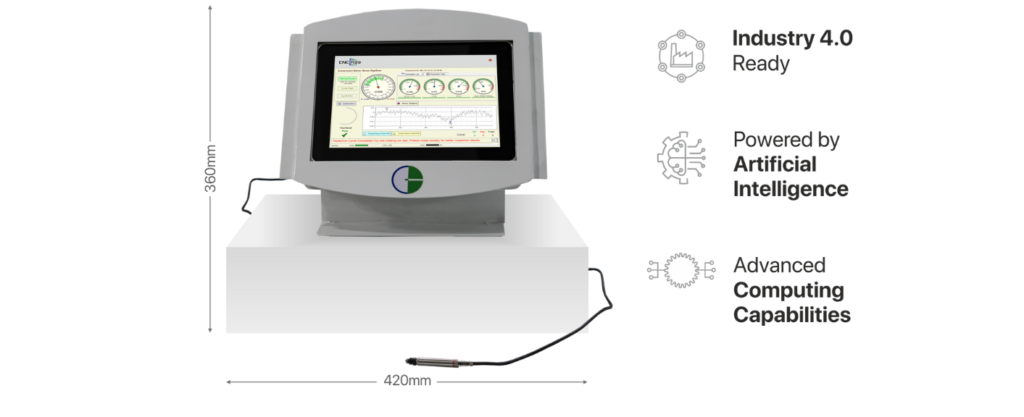

CNCtize is powered by CMGM patented Continuous Monitoring and

Guide Module and an Artificial Intelligence Software.

Results

15% Reduction in Rework

Significant decrease in rejected assemblies.

Improved Quality Control

Enhanced detection of defects and precise measurements.

Boosted Productivity

Increased operational efficiency and reduced downtime.

Cost Savings

Lowered financial losses associated with rework and rejects.

CalibroMeasure introduced CNCtize an Automation process of gear inspection and data recording which give 99.8% accuracy to the gearbox manufacturer

Key benefits of CNCtize

Automated Accuracy

CNCtize guarantees precise inspections, removing the variability and mistakes associated with manual processes.

Reduction in Rework

With its superior detection capabilities, CNCtize helps lower rework rates, leading to cost savings and improved manufacturing efficiency.

Increased Efficiency

By automating the inspection process, CNCtize significantly reduces inspection times, boosting overall productivity.

Comprehensive Quality Control

The system thoroughly checks all gears, ensuring that all quality parameters are met without exception.